OrideTech High Quality Engineering Services and Products

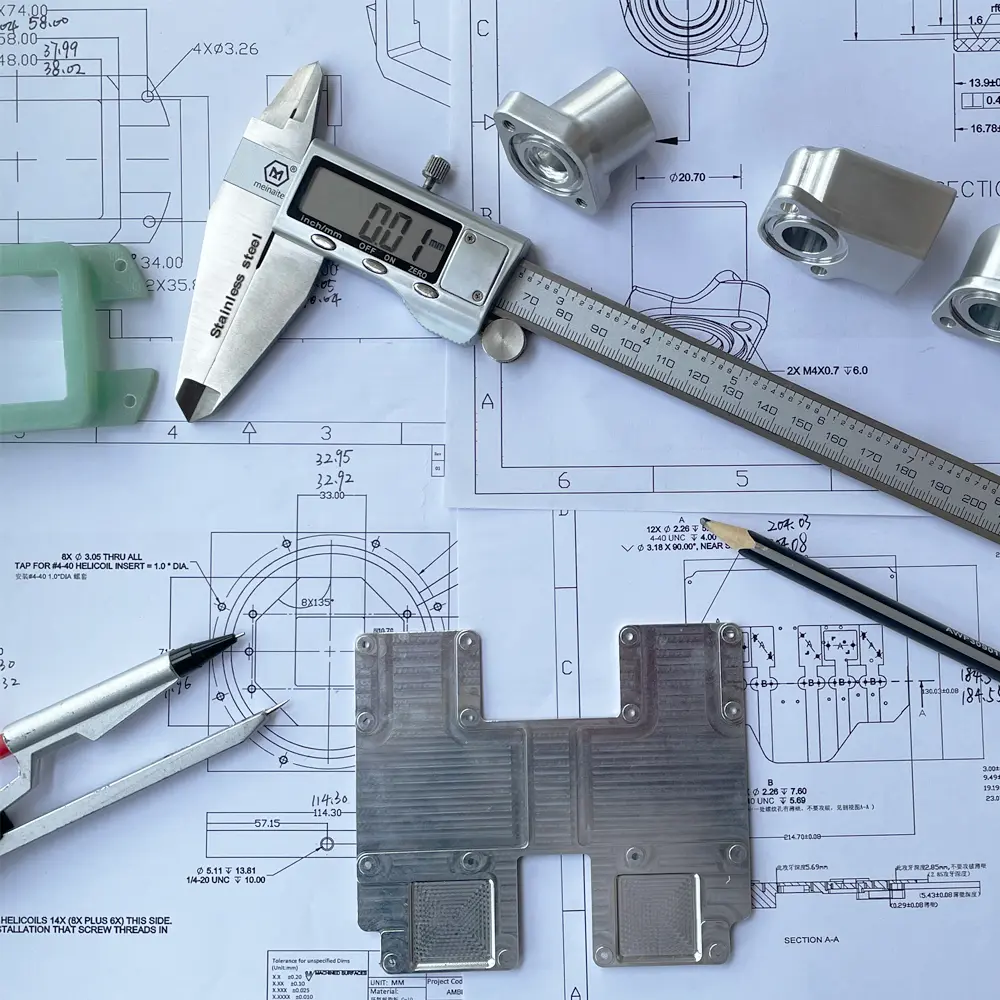

OrideTech can provide you high quality engineering services and products. We can provide 3D modeling and modifying, 2D drawing releasing, manufacturing process design and DFM analysis report.

If you need prototyping products, but only have a sample on hand, then, OrideTech can help you to create 3D modeling and release 2D drawing. Then, we can make prototyping samples and low-volume production products. When you already have 3D model and 2D drawing, we can help you to evaluate these designs from manufacturing. And we also help to make prototyping samples and low-volume production products. If you want to made some prototyping samples at OrideTech and need to do mass production, we can provide you manufacturing process flow to ensure your mass production running smoothly.

At Oride, we can provide you high level engineering services & products. For more details and videos, you can review on our Facebook page or YouTube channel.

What is DFM (Design for Manufacturing)?

DFM (Design for Manufacturing) is an important process in engineering services and products. It can evaluate and optimizes your designs for efficient and cost-effective manufacturing, assembly and testing. This work needs to take manufacturability, materials selection, assembly processes, and other factors into consideration. OrideTech use DFM to improve the efficiency and quality, reduce costs, and increase the speed. The DFM also helps to ensure that the final product meets the requirements of the end-user while minimizing production issues and reducing waste. In order to create an effective DFM, OrideTech guys always communicate with designers on all the details of manufacturing, design intent, function and using environment.

Principals of DFM (Design for Manufacturing) in Engineering Services and Products

Process:

The manufacturing process chosen must be correct. To choose process, the quantity of parts being made, the material being used, the surfaces and tolerance requirements and whether the other processes are needed.

Design:

Design is essential. The actual drawing of the part or product has to conform manufacturing process you’ve chosen. OrideTech engineers are willing and experienced to provide proper process for your design.

Material:

Some material properties need to be considered during DFM including mechanical properties, optical properties, thermal properties, color, electrical properties, flammability and even the stock supplying.

Environment:

Your parts must be designed to withstand the environment it will be subjected to. All the form in the world won’t matter if the part can’t function properly under its normal operating conditions.

Compliance/Testing:

All products must comply with safety and quality standards. Sometimes these are industry standards, others are third-party standards and some are internal, company-specific standards.

Advantages of an Effective DFM in Engineering Services and Products

The outcomes of an effective DFM include lower production costs, faster time-to-market, higher product quality, better functional performance, greater reliability, and improved customer satisfaction. Prototype DFM services are essential for product development as they allow designers to test and validate their designs before committing to full-scale production. Prototyping DFM also enables designers to identify design flaws, optimize designs, and reduce the risks associated with mass production. OrideTech guys always provide mechanical design hints include minimizing the number of unique parts, standardizing part sizes and materials, designing for manufacturability, optimizing assembly processes, and using simulation tools to test and optimize designs to customers. These proposals and hints can help customer to save their developing cost and expedite their developing cycles.

OrideTech Hints on Prototype in Engineering Services and Products

Avoid tall and thin walls, narrow gap, small pocket and the features you may not need.

Avoid interlock, deep holes, small or raised text and features that you may not need.

Add radius to internal corner of pocket, chamfers to holes top and tapered at the hole bottom.

Provide the relief to corner pockets and keep the enough space for T cutter features.

Choose common material or stock material or lower MOQ material to you design if possible.

Choose common extrusion profile for heat sinks and enclosure parts if possible.