What Are Rapid Prototyping Services?

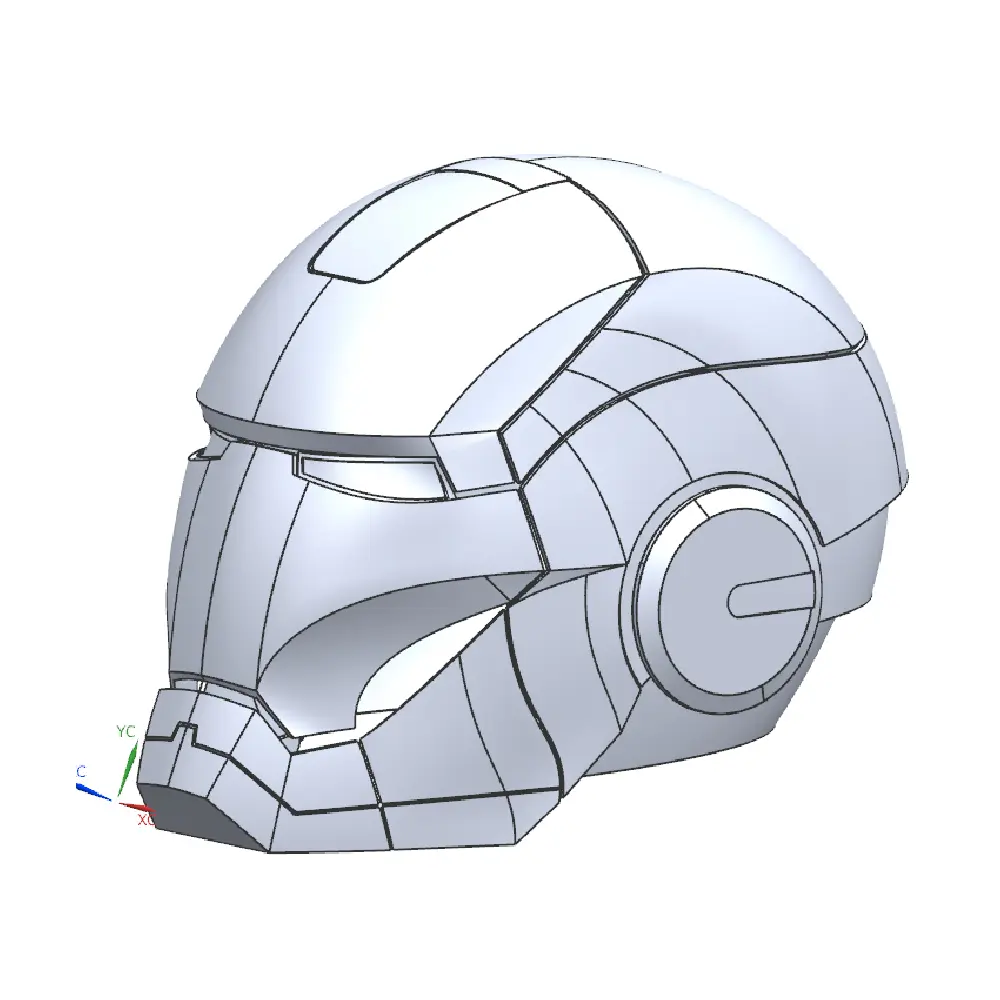

Rapid prototyping services is a process of quickly creating a physical or digital model of a product or part using computer aided design (CAD) software, 3D printing, or other manufacturing technologies. The purpose of rapid prototyping services can quickly and efficiently test and refine a design concept before investing. It allows designers and engineers to iterate on designs. And it makes changes based on feedback, ultimately resulting in a better final product.

Rapid prototyping is commonly used in industries such as product design, engineering, and manufacturing. OrideTech prototyping services provide you CNC machining, sheet metal fabrication, vacuum casting, finishing and relative engineering service. Their engineering services include 3D modeling, 2D drawing releasing, 3D model verification and modification. OrideTech invested these resources to provide you one-stop rapid prototyping service to save your developing time and cost. OrideTech has been working in rapid prototyping since 2013 and be very professional in rapid prototyping. For more details and videos, you can review on our Facebook page or YouTube channel.

How to Choose the Right Rapid Prototyping Services?

Choosing the right rapid prototyping services depends on several factors. It includes the type of product, the materials used, the accuracy, budget and schedule of the project. Here we provide some steps to help you choose the right rapid prototyping services:

- Determine the purpose of the prototype: Are you creating a prototype for assembly and fit testing, functional testing, or for display in exhibition purposes? The purpose of the prototype will affect the required level of accuracy and processes.

- Consider the materials: Different rapid prototyping techniques work best with different materials. For example, 3D printing is well-suited for plastics and resins, while CNC machining is better for metals and harder materials.

- Evaluate the required level of accuracy: Some rapid prototyping techniques, such as CNC machining process can produce highly accurate and complex features parts, vacuum casting can provide you faster lead time plastic parts and sheet metal can provide you metal parts in short lead time.

- Assess the budget and time: Some rapid prototyping techniques such as spark EDM and wire EDM may be more expensive or time-consuming than others. Some techniques such as vacuum casting may be very cheap for making plastic parts.

- Consult with experts or rapid prototyping vendors: Consult with experts or rapid prototyping vendors such as OrideTech in the field of rapid prototyping to determine the best technique for your designs. They can provide valuable proposals and recommendations based on their experience and expertise.

When I need Rapid Prototyping Services?

Rapid prototyping services are useful for designers and engineers who need to create physical prototypes of a design quickly and efficiently. It is important to businessman who want to make some samples to test their market. And the services are helpful to graduates who want to make their graduation projects come true.

- Concept validation: It can help you quickly create a physical prototype to validate your concept and test its feasibility.

- Design iteration: It allows you to quickly make changes to your design and create new prototypes to test it.

- Innovation: It can help you explore new design ideas and push the boundaries of what is possible. By quickly creating and testing new prototypes, you can identify innovative solutions to design challenges.

Advantages of OrideTech Rapid Prototyping Techniques

There are several advantages of OrideTech rapid prototyping:

- Faster design iteration: OrideTech rapid prototyping services allow designers and engineers to quickly create and test multiple design iterations, speeding up the design process and reducing the time to market.

- Reduced costs: By identifying design flaws and making changes early in the design process, OrideTech rapid prototyping can help reduce the cost of production by minimizing the need for expensive rework or tooling.

- Improved communication: Physical prototypes can be used to communicate design concepts and ideas to stakeholders, such as clients or investors, more effectively than 2D drawings or computer models.

- Better product quality: The rapid prototyping service can help identify potential issues with a design before it goes into production, resulting in a higher quality final product.

- Increased innovation: It encourage experimentation and innovation by allowing designers to quickly and easily test new ideas and concepts. This can lead to breakthroughs and new product developments that would not have been possible with traditional design methods.