What finishing technologies Can OrideTech Provide?

OrideTech can provide you many finishing technologies such as anodize, electroplating, painting, sand blasting and laser engraving. If you run your prototyping or low-volume production samples with finishing in OrideTech. Please email us with your requirements. Whether metal or plastic parts, we will provide you best finishing technologies and make your parts in good finishing. Generally, the finishing processes need 2-3 days lead time. If you have any urgent project, please let us know and we will assign special person to track and ship your samples during different processes to save time. For more details and videos, you can review on our Facebook page or YouTube channel.

Anodizing

Anodizing is an electrochemical process of finishing technologies. It can increase the thickness of the natural oxide layer on a metal surface, typically aluminum. Also, it involves immersing the part in an electrolyte solution. The process applies a current to form an oxide layer on the surface. In case that you need protective, decorative, or functional coating on aluminum parts, this is a good choice. Besides, it can improve the parts’ wear resistance, corrosion resistance, and electrical insulation properties. OrideTech provide you the anodize service which also can make your samples in specified colors. And this process can accept low quantity parts from prototyping or low-volume production.

Electroplating

Electroplating is a finishing technology which used to deposit a thin layer of metal onto a surface. It processes the parts through an electrochemical reaction. Electroplating is commonly used to improve the appearance or functionality of parts, such as adding a decorative coating or improving the part’s wear resistance or conductivity. OrideTech provide you the process to improve appearance, increase wear resistance, enhance corrosion protection and improve electrical conductivity to your parts. We can control the process parameters like plating material, composition and concentration of the plating solution, the current density applied, and the duration well. This is the basic actions to make your parts in good finishing and good looks.

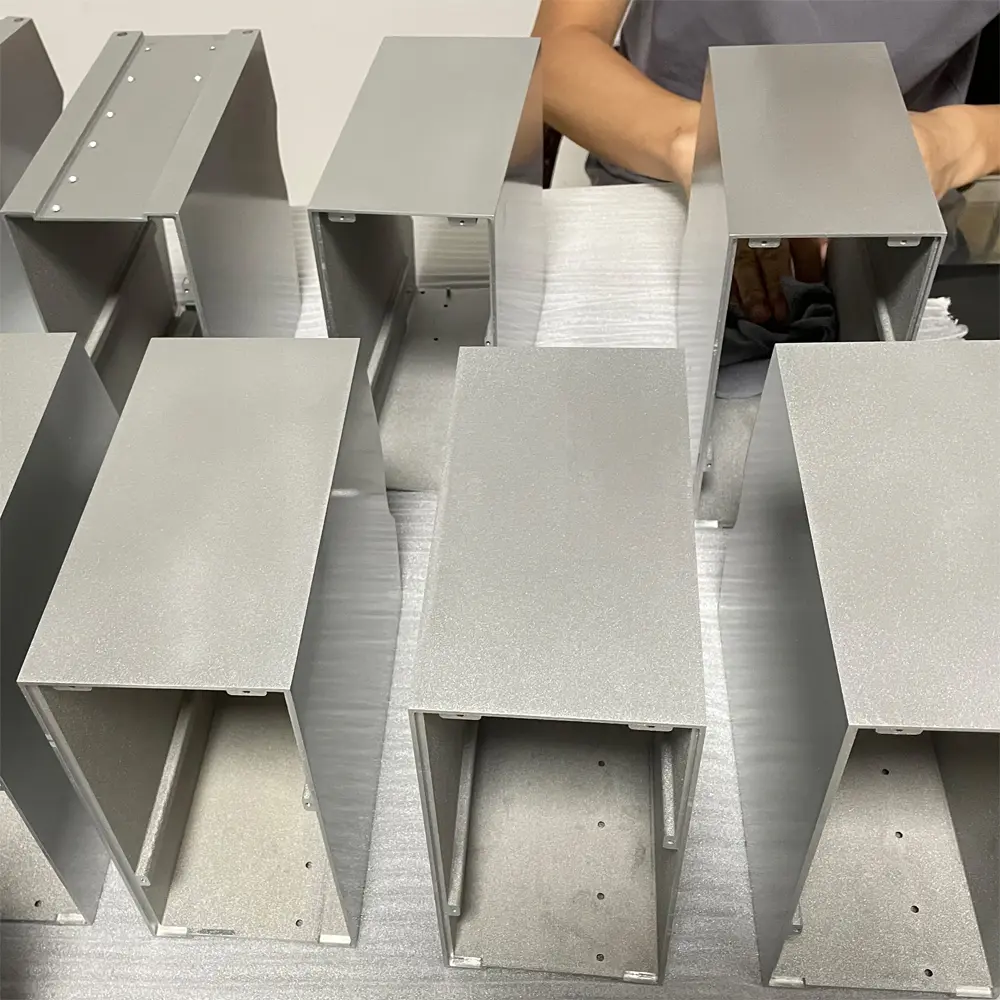

Painting

Painting is a finishing technology which used to apply a coating of paint to a surface. It involves cleaning and preparing the surface. Then it applies one or more layers of the desired paint or coating. If you need a decorative, protective, or functional coating on your part, this is a good choice. The process can enhance appearance, improve corrosion resistance, increase durability, and provide other benefits. OrideTech provide painting service to improve appearance, corrosion resistance, durability, and protection against the elements to your parts in rapid prototyping and low-volume production.

Sand Blasting

Sandblasting is a finishing technology which used to prepare a surface by forcibly propelling abrasive materials sand onto it. This process removes surface contaminants and roughens the surface to promote better adhesion for coatings or other finishing treatments. If your need painting or coating on your parts, sand blasting can help to clean purposes. OrideTech provides you sand blasting process to improve adhesion for coatings. And it also creates specific surface textures to your parts from rapid prototyping or low-volume production. We can control the parameters like blasting media, the air pressure and flow rate, the distance between the nozzle and the surface being blasted and the duration of the process well to make your parts in good finishing.

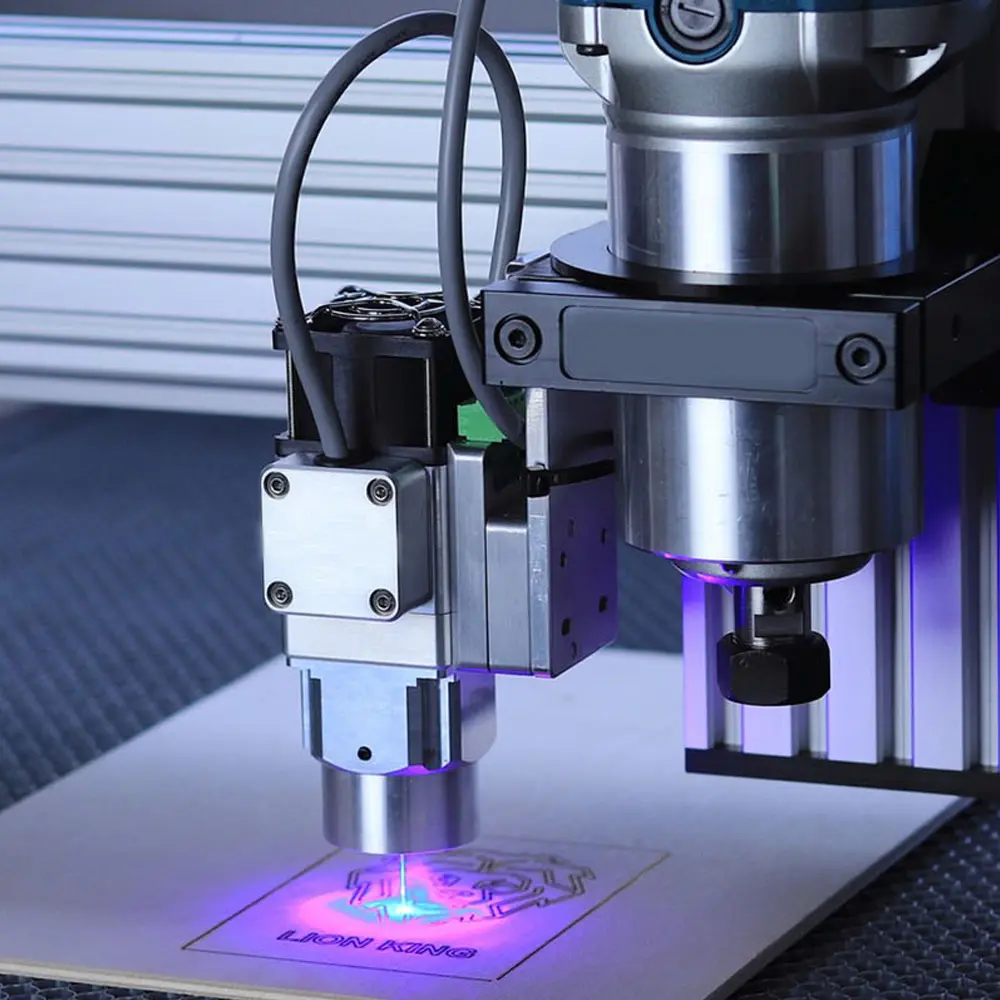

Laser Engraving

Laser engraving is a technique that uses a laser beam to remove material from surface and create permanent markings. OrideTech uses it on both metal and plastic parts. If customers require to make precise and permanent markings, logo or text on their parts, we adopt it. OrideTech’s laser engraving has high precision, permanence, versatility and the ability to create detailed and intricate designs. We can control the laser marking parameters like laser power, pulse rate, speed and focus distance well for engraving your parts with clear and good looks markings.

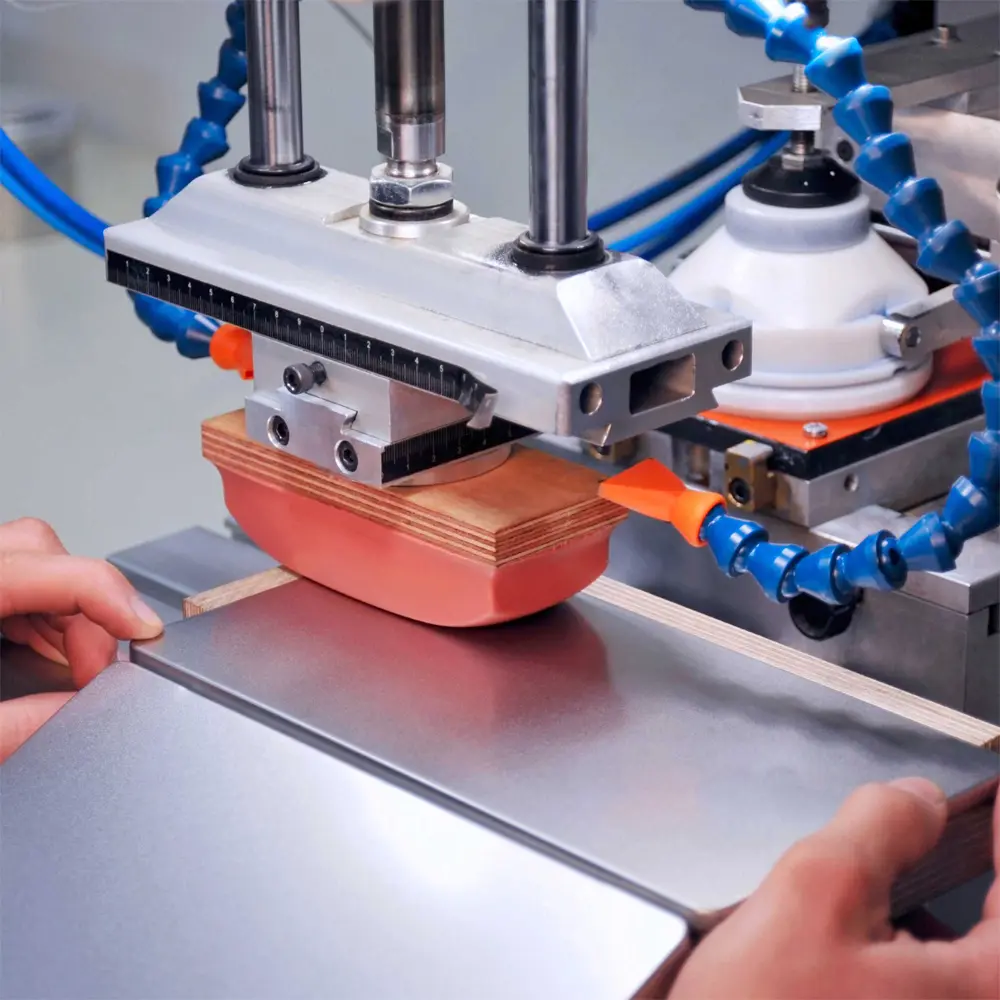

Pad Printing

Pad printing is a finishing technology that involves transferring ink from a silicone pad onto a variety of surfaces. It can work on both plastic and metal parts. The image or design is created on a printing plate. And the ink is picked up by the pad and transferred to the product surface. If the customers required to print text or some other designs onto their prototyping or low-volume production parts, OrideTech will adopt this process. The pad printing has advantages like versatility and durability. It always be welcomed by customers. We can control the process parameters such ink, pad hardness, pad shape, the pressure and drying time of the ink well for your prototyping or low-volume production parts.